Beckwith Machinery Company of Murrysville, Pennsylvania (Now Cleveland Brothers), is one of the largest Caterpillar dealers in America, with sales, service and manufacturing facilities in Pennsylvania and West Virginia. Their Cranberry, Pennsylvania facility also has a large rental business. When the machines are returned, many are loaded with mud, grease and oil. The mud can be removed simply by washing the machine, but the grease and oil are another matter.

Federal and local Environmental Protection Agency regulations require that water returned to its original source be free of commercial contaminants. The dilemma facing Beckwith: how to economically remove grease and oil from the water used to clean equipment so it can be safely returned to the Cranberry Township sewer system.

Washing is the first step of the cleaning process. The water used to wash the truck goes into a holding tank where mud and other debris are removed. The mud and debris, with oil clinging to them, are placed in a plastic-lined trash container and taken to a landfill.

“The second step required a bit more thought,” says Tom Fitzsimmons, plant superintendent for the Cranberry facility. “We had to make sure the uncollected oil that remained behind in the first holding tank was removed from the water as it moved into the second holding tank so it could then safely go back into the sewer system.”

That’s where the Oil Skimmers Inc.’s waste oil recovery system came in. The Oil Skimmer is designed to remove petroleum – based oils, animal and vegetable fats, greases and oil wastes floating on water. It comes in two models. The Model 6V, designed for larger projects, can remove 100 gallons of oil per hour. The Model 5H is designed for cramped, congested or tightly confined areas. Beckwith purchased a Model 6V Oil Skimmer mounted on a 60-inch frame.

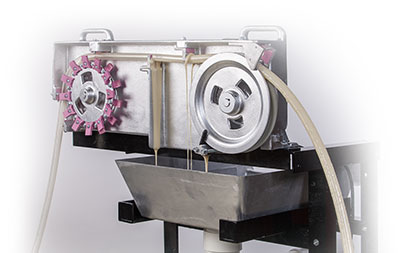

The company uses the Oil Skimmer at the second holding tank to remove the floating oil using a 28-foot-long Free-Floating Collector Tube®. Oil adheres to the outside of the closed loop tube, which is drawn through scrapers to remove the oil. The recovered oil is collected in a 55-gallon drum. The clean tube is returned to the water to collect more oil. The collected oil is recycled, and the clean water from the tank is released into the sewer system. Each month Beckwith retrieves about 465 gallons of recyclable oil.

The Oil Skimmer Model 6V can run 24 hours a day, and withstand temperatures up to 200 degrees and well below freezing. The Model 6V has been used in bus garages and military vehicle washdown facilities. It has also been utilized in maintenance and cleaning facilities for buses, mining equipment, bulk transportation tankers, and airplane and railway engines. The polyurethane tube can be sized to specification.

“We’ve run the oil skimmer eight to 16 hours a day since it was installed in 1995 and we’ve never had a breakdown,” says Fitzsimmons.